산업용 네트워크 | Autonics 대한민국

산업용 네트워크

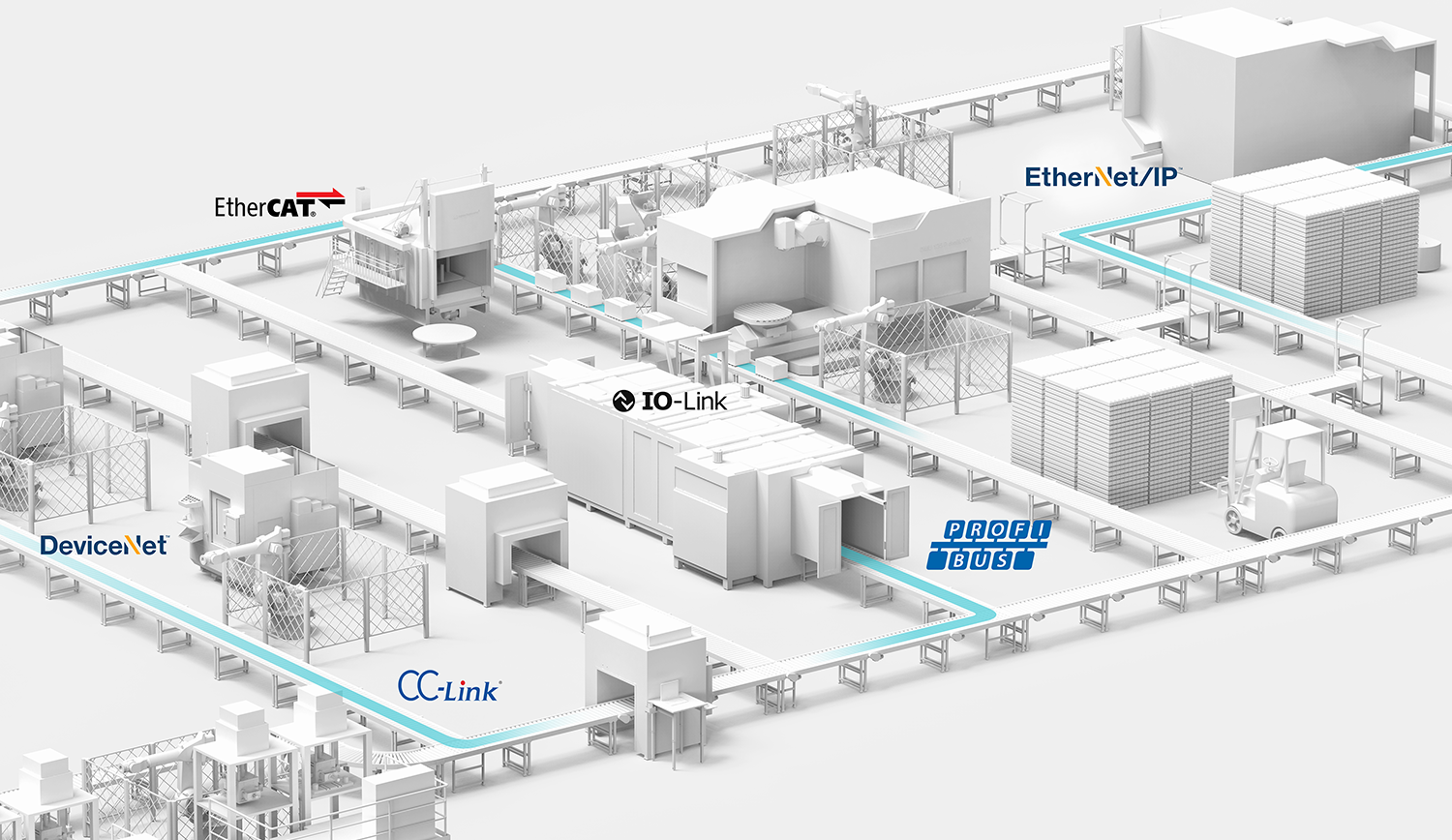

Make Industry Connected

산업 자동화의 성공은 신뢰성과 효율성을 갖춘 통신 네트워크에 달려있다고 해도 과언이 아닙니다.

현장은 점점 더 많은 산업용 장비들로 구성되기 때문에

공장 내 모든 구성 요소가 안전하고 강력하게 연결될 수 있도록 만드는 것이 산업 자동화의 성공을 좌우합니다.

오토닉스는 현장 내 모든 구성 요소가 유기적으로 연결될 수 있도록 산업용 통신을 지원하는 제품군을 제공하며

자동화 시스템이 효율적으로 구축될 수 있도록 지원하고 있습니다.

현장은 점점 더 많은 산업용 장비들로 구성되기 때문에

공장 내 모든 구성 요소가 안전하고 강력하게 연결될 수 있도록 만드는 것이 산업 자동화의 성공을 좌우합니다.

오토닉스는 현장 내 모든 구성 요소가 유기적으로 연결될 수 있도록 산업용 통신을 지원하는 제품군을 제공하며

자동화 시스템이 효율적으로 구축될 수 있도록 지원하고 있습니다.

현장의 중추적인 역할, 산업용 통신

통합성

생산 현장 전반에 걸친

데이터

교환으로 시스템 통합 실현

교환으로 시스템 통합 실현

효율성

생산 시스템에

유연함과

효율성 제공

효율성 제공

혁신성

개방형 프로토콜과

솔루션으로

현장 혁신 실현

현장 혁신 실현

안정성

정확하고 안정적인

데이터 전송 가능

데이터 전송 가능

신뢰성

기기 및 시스템

유지에 있어

신뢰성 향상

신뢰성 향상

인더스트리 4.0, 스마트 팩토리 등 제조업 혁신에 따른 스마트 공장이 이슈화되면서 산업용 네트워크 기술에도 관심이 높아지고 있습니다.

산업용 네트워크는 현장에 독립적으로 존재하는 디바이스와 시스템을 하나의 네트워크 안에서 연결을 통해 데이터의 정보 교환을 가능케하며 이는 생산 현장의 효율성과 생산성 향상을 실현하게 해주는 중요한 역할을 합니다.

산업용 네트워크는 적시에 데이터를 획득하고 전달하며 갈수록 늘어가는 데이터의 양을 처리할 수 있도록 진화하고 있습니다.

이에 산업용 네트워크는 필드버스 프로토콜에서 시작하여 간편한 연결과 빠른 속도, 더 많은 장비와의 연결이 가능한 산업용 이더넷 프로토콜로 확장하며 통합성, 효율성, 혁신성, 안전성 그리고 신뢰성을 바탕으로 지속 발전하고 있습니다.

한 눈에 보는 산업용 네트워크

다품종 소량 생산의 시대가 도래함에 따라 빠르고 간단한 자동화 시스템이 각광받게 되었습니다.

이에 따라 생산 설비를 효과적으로 운용하기 위한 네트워크의 필요성이 대두되었고 이를 위해 산업용 네트워크가 등장하게 되었습니다.

초기의 계측 및 제어 데이터 수집은 입출력 값을 1:1로 접속 운용하였던 아날로그 방식이었지만 이후 디지털 방식으로 전환되었습니다.

현재는 산업용 네트워크는 필드버스(Fieldbus)와 산업용 이더넷이 혼재되어 사용되고 있습니다.

이에 따라 생산 설비를 효과적으로 운용하기 위한 네트워크의 필요성이 대두되었고 이를 위해 산업용 네트워크가 등장하게 되었습니다.

초기의 계측 및 제어 데이터 수집은 입출력 값을 1:1로 접속 운용하였던 아날로그 방식이었지만 이후 디지털 방식으로 전환되었습니다.

현재는 산업용 네트워크는 필드버스(Fieldbus)와 산업용 이더넷이 혼재되어 사용되고 있습니다.

통신 인터페이스별 프로토콜 종류

두 개 이상의 장치가 통신을 하려면 통신 인터페이스와 통신 프로토콜이 일치해야 합니다. 통신 인터페이스는 통신 포트의 물리적 규격을 말하여

통신 프로토콜은 데이터 통신을 하기 위한 규칙을 의미합니다. 현재 다양한 협회에서 통신 프로토콜의 표준을 관장하고 있습니다.

※ 하기에서 언급되는 통신 프로토콜은 오토닉스에서 지원하는 주요 통신 프로토콜에 한해 기재되었음을 알려드립니다.

산업용 이더넷

Industrial Ethernet

장치, 제어, 정보까지 세 개의 계층이 서로 다른 네트워크를 사용했던 기존 필드버스의 환경에서 4차 산업혁명의 시대가 열리고 IoT 개념이 부상하면서 각 계층별 네트워크를 하나로 통합할 필요가 증가하며 제조 현장에 산업용 이더넷이 급격히 확산되고 있습니다. 산업용 이더넷은 빠른 전송 속도와 실시간 제어 기능 그리고 뛰어난 호환성으로 산업 현장의 네트워크를 구축하고 있습니다.

필드버스

Field Bus

필드버스는 산업용 자동화 시스템의 센서부, 제어부, 출력부의 데이터를 신뢰성 있고 노이즈에 강한 형태로 전송하는 산업용 네트워크입니다. 디지털 방식을 기반으로 하고 있어 기존 아날로그 통신 방식에 비해 다량의 신호를 원거리까지 전송할 수 있고 각각의 현장 기기나 입출력 모듈의 엄청난 가닥 수를 가진 케이블 대신 한 가닥의 네트워크선을 사용하기 때문에 배선 절약 및 설치가 용이합니다.

오토닉스 통신 지원 제품

오토닉스는 필드버스 및 산업용 이더넷 통신 인터페이스를 기반으로 한

다양한 프로토콜을 지원하는 제품을 제공하며 고객의 통신 요구를 충족하고 있습니다.

신뢰할 수 있는 오토닉스 제품으로 효율적인 현장 구현을 실현하시기 바랍니다.

다양한 프로토콜을 지원하는 제품을 제공하며 고객의 통신 요구를 충족하고 있습니다.

신뢰할 수 있는 오토닉스 제품으로 효율적인 현장 구현을 실현하시기 바랍니다.

통신 프로토콜

제품군

센서

-

레이저 변위센서

(레이저 변위센서 전용 통신 컨버터) -

광화이버 센서

(광화이버 앰프 전용 통신 컨버터)

머신비전

-

스마트 카메라

필드계기

-

압력센서

-

온도센서

컨트롤러

-

온도조절기

-

온도조절기

-

온도조절기

-

온도조절기

-

온도조절기

-

온도조절기

-

온도조절기

-

온도조절기

-

기록계

-

기록계

-

기록계

-

HMI

-

HMI

-

HMI

-

HMI

-

HMI

-

HMI

-

판넬메타

-

판넬메타

-

지시계

-

지시계

-

디스플레이유닛

-

카운터/타이머

전력기기

-

전력조정기

-

전력조정기

-

전력조정기

-

전력조정기

모션 디바이스

-

클로즈 루프 스테핑 시스템

-

클로즈 루프 스테핑 시스템

-

모션 컨트롤러

산업용 네트워크

-

리모트 I/O 시스템

-

리모트 I/O 시스템

-

네트워크 컨버터

컨트롤러

-

온도조절기

-

온도조절기

전력기기

-

전력조정기

센서

-

매핑센서

-

매핑센서

모션 디바이스

-

클로즈 루프 스테핑 시스템

산업용 네트워크

-

리모트 I/O 시스템

컨트롤러

-

HMI

-

HMI

산업용 네트워크

-

리모트 I/O 시스템

-

리모트 I/O 시스템

산업용 네트워크

-

리모트 I/O 시스템

센서

-

근접센서

-

초음파 센서

-

근접센서

-

리니어 포지셔닝 센서

산업용 네트워크

-

리모트 I/O 시스템

필드계기

-

온도전송기

-

온도전송기

센서

-

스마트 카메라

컨트롤러

-

온도조절기

-

HMI

-

HMI

-

HMI

-

HMI

-

HMI

-

HMI

-

기록계

-

기록계

모션 디바이스

-

클로즈 루프 스테핑 시스템

산업용 네트워크

-

리모트 I/O 시스템

산업용 네트워크

-

리모트 I/O 시스템

-

리모트 I/O 시스템

산업용 네트워크

-

리모트 I/O 시스템

-

리모트 I/O 시스템

센서

-

매핑센서

-

매핑센서

전력기기

-

전력조정기

모션 디바이스

-

클로즈 루프 스테핑 시스템

-

클로즈 루프 스테핑 시스템

산업용 네트워크

-

리모트 I/O 시스템

-

리모트 I/O 시스템